The soft lithography space, Soft Materials Clean Room (SMCR) is located in SEC 2.125, is a class 10,000 cleanroom and is designed for microfluidic device fabrication and characterization.

Capabilities

An oxygen plasma cleaner from Diener is available for sample cleaning and material surface pretreatment. A spin coater from Laurell is installed in the fume hood for spin coating photoresist and PDMS polymer up to 4000 rpm. A broad band UV mask aligner from ABM is available for exposing both positive and negative tone photoresist. Finally, a speed mixer from FlackTek is available for mixing PDMS and any other polymeric material before cast molding.

The stylus profilometer can perform contact measurements of device surface roughness, topography, or thin film thickness.

The Keyence digital microscope can perform optical imaging, producing high-resolution images at up to 2000X.

Equipment Summary

| Diener plasma cleaner | Laurell spin coater |

| FlackTek speed mixer | stylus profiler |

| ABM mask aligner | Keyence optical microscope |

Equipment Details

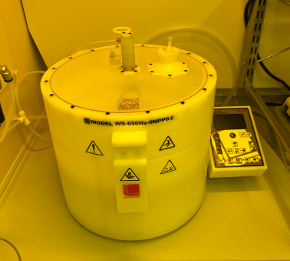

Laurell Spin coater

•Make: Laurell Technologies

•Model: WS-650Mz-8NPPB

•The Laurell Technologies spin coater is available for spin coating SU-8 photoresist and PDMS onto glass or silicon substrates. We have multiple vacuum chucks and adapters that allow processing substrates of various shape and size, including small fragments, up to 200mm in diameter. It can be programmed with multi-step recipes with a maximum spin speed of 12K RPM and maximum acceleration of 12K RPM/Sec.

ABM MASK ALIGNER

•Make: ABM

•Model: ABM/8″/500w/NUV/DCCD/SEMI AUTO

•This mask alignment and exposure system has a table-top configuration and offers Near UV (365nm (I line) and 400nm (H line)) exposure capabilities. It is a contact aligner with precision x, y, z and substrate rotation controls. It has a dual-field high magnification microscope for alignment. We provide two circular vacuum chucks capable of processing 3”/4” and 6”/8” wafers with Wedge Compensation (Planarizing) feature. The aligner has two mask holders for 5”x5” and 9”x9” sized masks, ideal for 3”/4” and 6”/8” wafers respectively. The minimum feature size that can be achieved on this system is about 2 micrometers. However, the practical limit will ultimately depend on the mask resolution, the photoresist type, thickness, uniformity, and the level of contact between the photoresist layer and the mask.

Diener plasma Cleaner

•Make: Diener

•Model: Atto

•The Diener Plasma Cleaner is a general use, fully programmable, plasma cleaner with large chamber size (8” diameter and 10” depth). This system runs on pure oxygen and is mainly utilized for cleaning samples and surface activation to facilitate PDMS-PDMS or PDMS-glass bonding. Custom recipes can be programmed and saved in the system. Parameters such as pump down pressure, gas flow rate, power, and run time can be easily input using the touchscreen interface.

Flacktek Speedmixer

•Make: FlackTek

•Model: DAC 1200-500 VAC

•The FlackTek SpeedMixer is utilized for consistent mixing of viscous materials. It is capable of mixing anywhere from 10 – 500 grams of material with the various mixing cup sizes provided. The SpeedMixer also has the ability to generate a vacuum inside the mixing chamber to prevent introducing gas into the material being mixed.

Keyence Microscope

•Make: Keyence

•Model: VHX-7000

•Fully capable model VHX with a manual stage, 12 megapixel camera, and fully integrated head with up to 2000x magnification. The entire head assembly can be tilted up to 90 degrees (horizontal) and can image samples from any angle in between. It includes 2D and 3D imaging and measurement, polarization, automated Z-motor, fully focused imaging, and advanced measurement software such as contamination analysis, grain analysis, automated area measurements.

Dektak Stylus Profilometer

•Make: Bruker

•Model: DektakXT

•The DektakXT stylus contact profilometer is the latest surface profiler with high vertical resolution (5nm) with large X/Y scan range for 2d and 3d surface analysis. All-purpose step-height measurement tool for film thickness and etch-depth.